ยินดีตอนรับเข้าสู่ Atom Instruments Service , Rent & Sale.

For more information about (Portable Coordinate Measuring Machine)

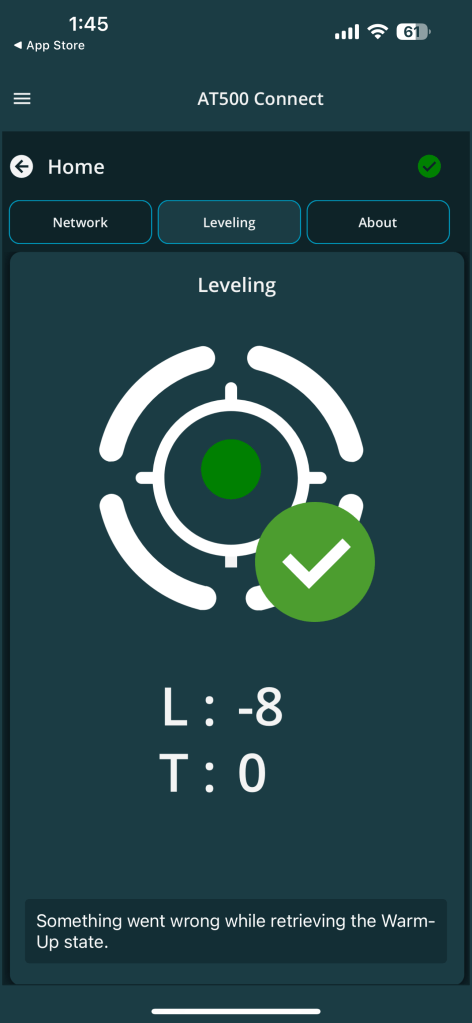

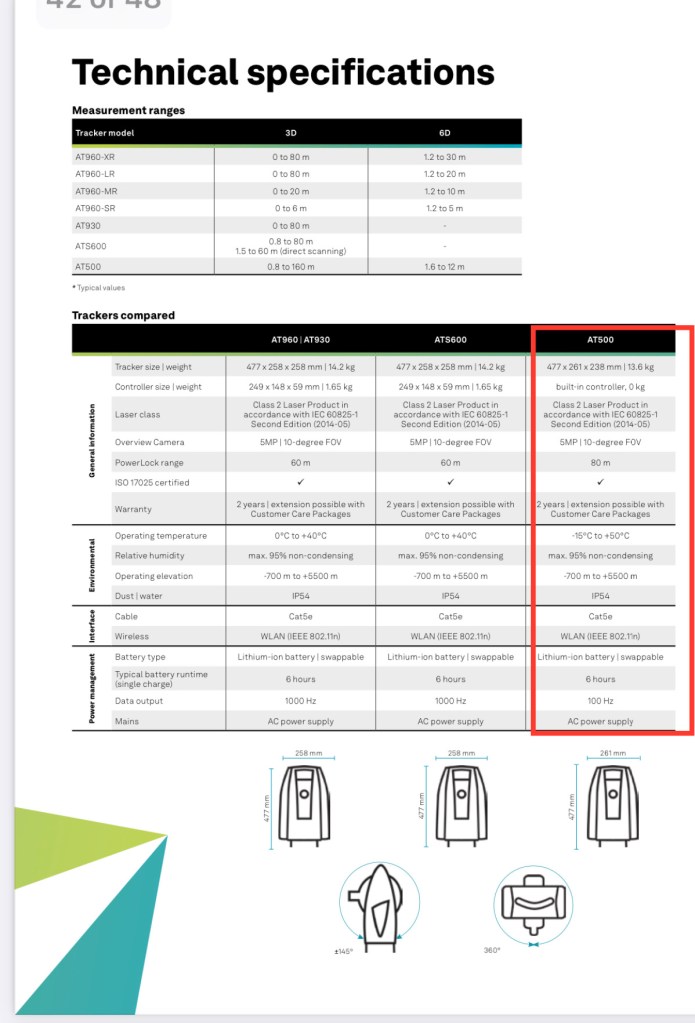

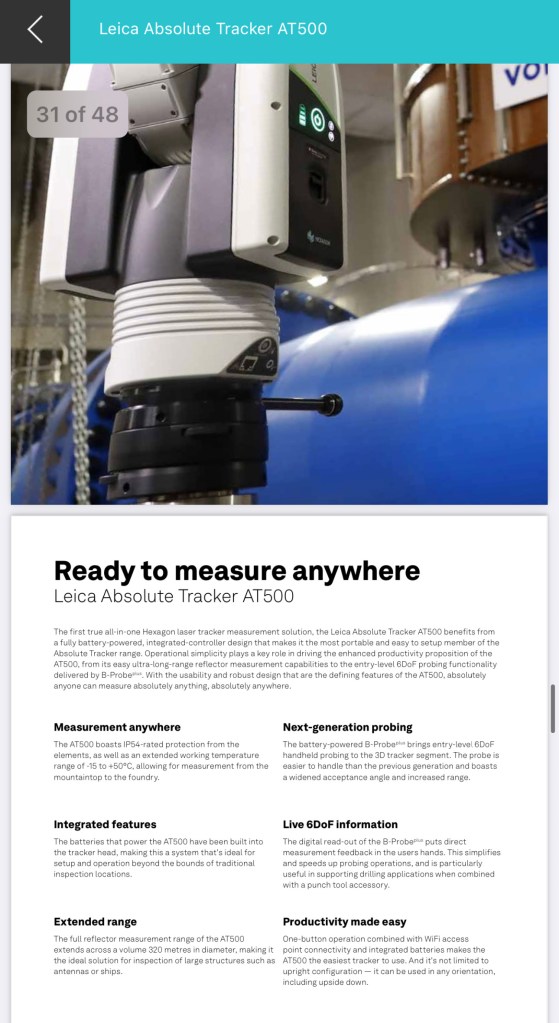

The new Leica Absolute Tracker AT500 simplifies the measurement of coordinates and dimensions for complexly structured workpieces. With its portability, easy setup, and ability to handle large-scale measurements effortlessly, the AT500 makes precision tasks a matter of simple steps. Featuring IP54-level protection and an extended operating temperature range, the AT500 performs reliably even in the most challenging conditions. From reflector measurements with a maximum range of 160 meters to the streamlined 6DoF inspection function (B-Probe+), the AT500 is ready to tackle any production or assembly challenge, regardless of size or location.

The B-Probe+ is a portable probing tool specifically designed for use with the Leica Absolute Tracker AT500. The B-Probe+ is capable of capturing 3D coordinate points, even in hard-to-reach or obscured areas, making it ideal for large-scale measurements. This wireless solution comes with a rechargeable battery that supports up to 6 hours of continuous operation. Its advanced design ensures that probing measurements are both simple and cost-effective, providing a reliable and affordable solution for precision measurement tasks.

The Laser Tracker AT403 is part of a portable coordinate measurement system. It is a measuring device that captures the 3D coordinates of an object by measuring angles and distances using interferometric and/or laser beam measurements. A laser beam is emitted directly from the laser tracker to a reflector, and the beam is then reflected back to the tracker. This process determines the distance. Additionally, the device encodes angles internally, detecting both vertical and horizontal angles between the laser tracker and the reflector. With this data (1. distance, 2. angles), the exact 3D position of the object can be calculated and determined.

To enhance speed and ease of operation, the Leica Tracker AT403 works seamlessly with inspection software such as PolyWorks, SpatialAnalyzer, and PC-DMIS.

The Leica Absolute Tracker AT403 is designed to support a wide range of tasks with high efficiency, affordability, and precision, while minimizing measurement processing time. This laser tracking solution enhances the speed and effectiveness of both static and continuous measurements, improving overall productivity. Its flexible station-switching capability saves time and optimizes workflow.

Furthermore, it features the latest innovations, such as WiFi connectivity for easier data access and instantly replaceable batteries, which provide greater operational flexibility and further enhance the efficiency of the entire measurement process.

In some cases, certain surface features or positions cannot be measured directly using reflectors. While relocating the station is one option, it does not always resolve the issue. Utilizing a Sphere Fit Adapter along with the necessary accessories can provide a cost-effective and accurate solution.

The Precision Level Track Motion Set-up using a Laser Tracker is a process that employs high-precision measurement tools to inspect the inclination of surfaces in both the horizontal and vertical planes. The Laser Tracker can measure high-low positions along the Z-axis, as well as positions along the X and Y axes of each Linear Rail on the Robot slide rails, ensuring that the object or system being inspected is accurately aligned to the desired level of precision.

Setting up levels with a Laser Tracker offers several benefits, including ease of reading and calculating coordinate values, reduced working time, and improved installation efficiency, which in turn extends the lifespan of machinery. Typically, Laser Trackers are used in applications requiring high precision, such as industrial production lines, machinery installation, surveying, and other tasks that demand exceptional accuracy and reliabili

Core Services

- Portable CMM Instrument Sales and Rental Services

- We provide portable Coordinate Measuring Machines (CMMs) for precise dimensional measurements across industries such as aerospace, automotive, and energy.

- Training Services

- Specialized training for operating Portable CMM Arms and Leica Trackers.

- Software proficiency training in PolyWorks, PC-DMIS, and SpatialAnalyzer.

- Calibration and adjustment services to ensure optimal instrument performance.

- Parts Inspection Services

- Precision inspection of parts to ensure compliance with quality standards and specifications.

- Production Line and Machine Installation: Position Adjustment and Verification

- Expertise in adjusting and verifying the installation positions of production lines and machinery to ensure accuracy and operational efficiency.

- 3D Scanning and Reverse Engineering Services

- High-precision 3D scanning and reverse engineering solutions to support product design, development, and optimization.

- Tube Inspection and Bender Machine Calibration Services

- Inspection of tubes and calibration of tube bender machines to ensure precision in fabrication and machine performance.

Contact us

Atom Instrument Service 2018 Co., Ltd.

29/24 Maneerin Modern Home Bowin, Moo 8, Bowin, Sriracha, Chonburi 20230 Thailand.

TAX ID : 0205564000372

Head office : atom2018service@atominstruments.com

(+66) 89 0541 504

Customer Service Supports : orots.muangtan@atominstruments.com

Line Contact : https://line.me/ti/p/oA6zNF-4Io

Company Map : https://goo.gl/maps/YxfvgqM5cFxNv9ZQ6

Atom Instrument Service 2018 Co., Ltd.